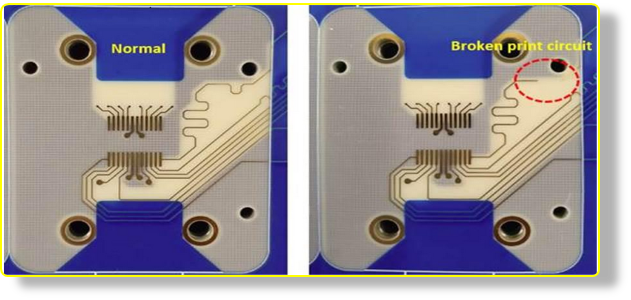

Dead or Alive

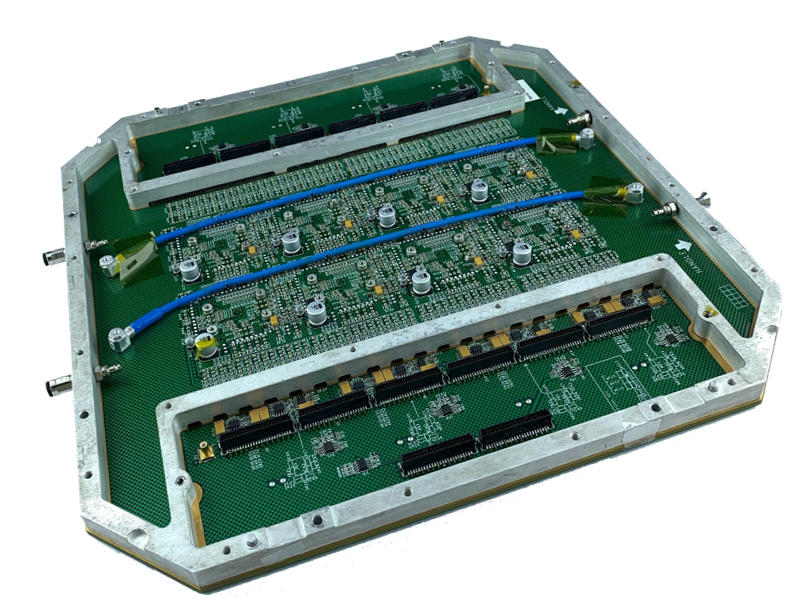

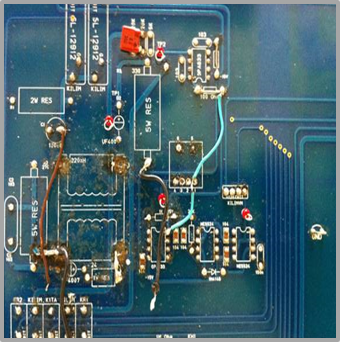

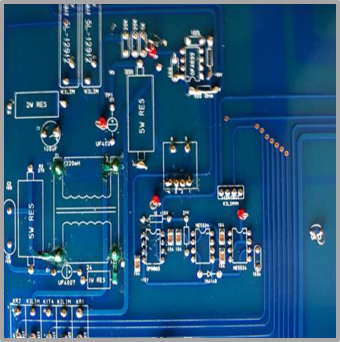

Alive on Delivery

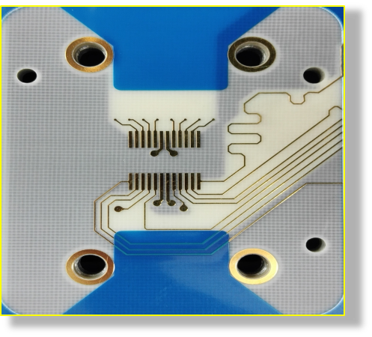

-Shortest delivery turn-around time for Loadboard test pads restoration.

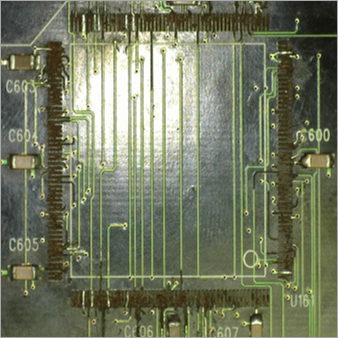

--Proven durability with longer tool life, more insertion.

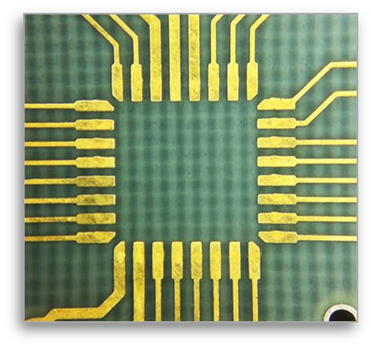

---Passed Analog, Mixed-signal and RF application.

NEED FOR SPEED?

NEED FOR SPEED?